Bavarian Center for Sustainable Fuels (ZENK)

The Center for Sustainable Fuels (ZENK) at the Fraunhofer Institutes IGB in Straubing and UMSICHT in Sulzbach-Rosenberg aims to develop new production routes for climate-neutral fuels based on CO₂, biomass and renewable electricity. The research work is being funded by the Free State of Bavaria with 11.9 million euros over a period of four years.

Liquid fuels with high energy density will continue to be needed in various areas of mobility in the future, such as aviation, shipping, agricultural vehicles, construction machinery, heavy-duty traffic and emergency vehicles. In order to meet climate targets, it is important that these fuels are produced in a climate-neutral way in the future. One way of doing this is to replace fossil fuels with regenerative carbon sources.

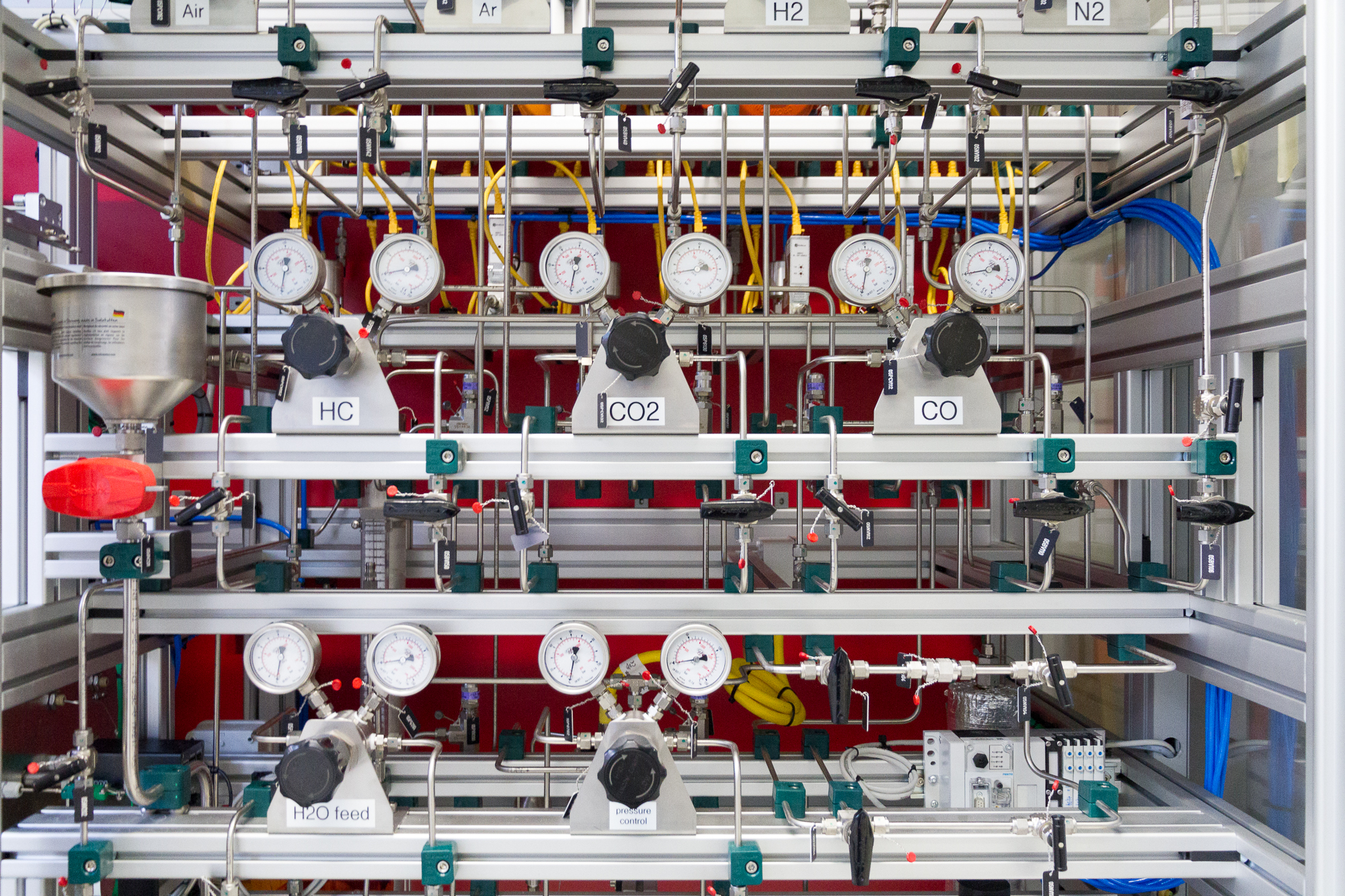

Within the framework of the ZENK project, the existing preliminary work of the Fraunhofer Institutes IGB at the Bio-, Chemo- and Electrocatalysis branch, BioCat, and Fraunhofer UMSICHT, Sulzbach-Rosenberg branch, in the field of sustainable fuel production will be combined. Here, a coupled pilot plant and development infrastructure will be established to enable the further path to industrial application and market introduction. Companies from the petrochemical industry are to be closely involved.

This project is funded by the Free State of Bavaria. For this reason, Hubert Aiwanger, Bavarian State Minister for Economic Affairs, Regional Development and Energy, came to the IGB in Straubing on June 29, 2023 to hand over the grant notification. »For me, the Center for Sustainable Fuels in Straubing and Sulzbach-Rosenberg is a key project for the future that can make a significant contribution to the energy transition and to securing the energy supply in Bavaria,« said Aiwanger. »After all, electromobility alone is not enough to make traffic climate-neutral. Existing vehicles as well as hard-to-electrify marine and aviation applications need renewable fuels.«

»For the energy transition in the transportation sector, we need huge quantities of sustainable fuels. New processes are needed for the required fuel production, as existing technologies alone are not sufficient," also explains Dr. Arne Roth, ZENK project manager at Fraunhofer IGB. "We want to develop such processes and must show that the new technical approaches work and deliver climate-friendly fuel solutions for tomorrow's mobility in an economically sensible way. With the ZENK platform, we can do just that.«

Combining biogenic production routes and PtX synthesis processes

In the ZENK approach, a combination of biogenic residues and waste materials, carbon dioxide (CO₂) and renewable electrical energy serves as the raw material basis for sustainable fuels. The synthesis and production routes for the utilization of these feedstocks will be combined, optimized and transferred to pilot plant scale. Regional energy and feedstock potentials will be considered and possible sites for industrial implementation will be evaluated. The long-term goal is the implementation of an integrated, sustainable refinery concept.

Specifically, a power-to-X production route and a production route based on thermochemical conversion of biogenic residual and waste materials will be coupled in the ZENK project:

In the power-to-X route, hydrogen is produced at Fraunhofer IGB by electrolysis of water using renewable energy. This is catalytically converted with carbon dioxide to methanol. The methanol is converted to higher olefins via various intermediates. These are processed in a hydrogenation process to form a mixture of saturated hydrocarbons, from which various types of fuel can be produced. The need for development lies in particular in the identification and testing of stable and selective catalyst systems and the adaptation of the plant operation to varying purities of the feedstocks and to the intermittent availability of renewable energies.

In the biomass-based route, a hydrogen-rich synthesis gas, a crude oil equivalent and a coal-like solid (biochar) are produced from biogenic residual and waste materials at Fraunhofer UMSICHT. »Here at UMSICHT, we place an emphasis on high-quality utilization of biogenic residues,« says Dr.-Ing. Robert Daschner, who heads the project on the UMSICHT side. »In order to use the limited resources in the highest possible quality, we want to identify and leverage the synergies between biomass utilization and Power-2-X applications - i.e. electricity-based fuel generation - as part of this project. To this end, we are developing technical solutions, for example, to provide hydrogen or carbon dioxide from biomass residue.«

The syngas produced from the biomass can be used in the methanol synthesis of the Power-to-X route. The biogenic oils can be upgraded to fuels via the existing hydrogenation process. In addition, the supply of methanol synthesis with as pure CO₂ as possible via an oxyfuel combustion process of the biogenic process gases (pyrolysis gas, sewage gas, etc.) will be tested. This in turn uses the excess oxygen produced during electrolysis. One focus of the research here is on conditioning the gases for the further synthesis steps.

Biochar, which is a product of thermochemical biomass conversion, plays an important role in the CO₂ balance of fuels. The carbon bound in it is permanently removed from the atmosphere, enabling overall CO₂-negative fuel production. The potential applications of biocoal in Bavaria are also being investigated as part of ZENK.

Timetable

The project is divided into two phases. In the first and already completed phase, from October 2021 to December 2022, the design, planning and commissioning of the components and equipment at both sites were completed. In the current second phase (January 2023 to September 2026), the processes will be gradually coupled and optimized after commissioning. In parallel, an ongoing life cycle assessment and techno-economic evaluation of the individual and overall processes as well as the fuels produced will be carried out.

Last modified: