New projects in Sulzbach-Rosenberg

DAnkEE Projekt - environmentally friendly exhaust gas cleaning by a new filter system

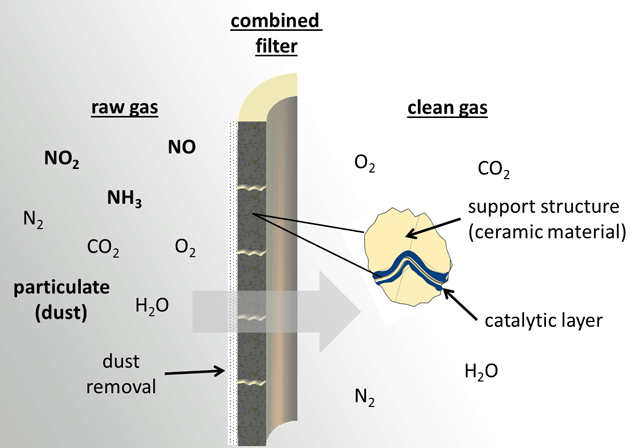

The BMWi-funded project DAnkEE - Demonstration of a plant for combined dedusting and denitrification - contributes to the efficient generation of heat and electricity from biomass by further developing exhaust gas purification. The plant technology developed in the project will serve to better utilize low-cost biomass residues and waste materials and to make this process environmentally friendly by means of a novel flue gas cleaning system.

The aim of the cooperation project is the demonstration of a combined exhaust gas cleaning system (EGR) for dust and nitrogen oxide reduction for biomass furnaces in the power range of 0.1 - 5 MW furnace heat output (FWL). The project reacts to the stricter emission requirements and shows a solution for the reduction of NOx and fine dust emissions.

Project process

In a first step, an innovative manufacturing process developed by Fraunhofer UMSICHT for SCR catalysts in the low-temperature range will be upscaled. The second focus of the research project is the testing of a demonstrator of the combined filter system in the Fraunhofer UMSICHT pilot plant under real conditions. Together with the filter manufacturer and project partner Herding Filtertechnik GmbH, a new type of filter is being developed that can simultaneously reduce NOx and separate fine dust.

Manufacture of marketable filter systems

Fraunhofer UMSICHT is responsible for manufacturing the catalysts and activating the filter elements. In the process, plants for the catalytic activation of filter elements must be built on a scale comparable to that of commercially available filter plants. All cleaning, surface activation and loading steps, which have to be individually adjusted depending on the carrier material, are carried out here. As a rule, the carrier structure is specifically cleaned with acid media and prepared for loading before the catalysts are applied. The previously loose and partially inactive materials are then firmly bonded to the carrier structure in the subsequent calcination process and specifically activated.

For evaluation purposes, the filter elements are installed in a specially designed filter and exposed to the exhaust gas of biogenic residues. The test series are also carried out in the Fraunhofer UMSICHT firing pilot plant.

Last modified: