Economical recovery of plastics, metals and energy from composites

From the chip bag to the smartphone to the car radio: Many of our Everyday products consist of a combination of materials that are used at the end of a life cannot be recycled using conventional processing methods. Complex blends of plastic types, the use of which is not mechanically separable plastic-plastic or plastic-metal composite or the content of old additives which, according to European legislation, are no longer used in recyclates may be contained, prevent material recycling. At the same time, the demand for high-quality recyclates and the recycling quotas for old products continue to rise. In order to meet these challenges, the Fraunhofer community project »kunstwerk« was initiated, in which the new technology combination is to be tested with interested producers and recyclers and established in practice.

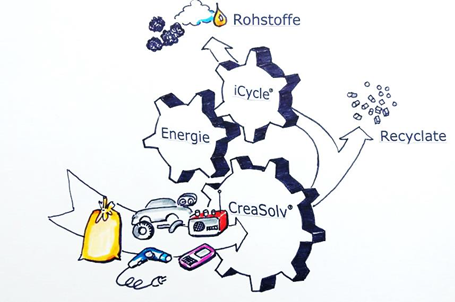

The Bavarian Fraunhofer Institutes IVV from Freising and UMSICHT from Sulzbach-Rosenberg couple two innovative Fraunhofer technologies in the project »kunstwerk - Combined plastic and metal recycling to high-quality new materials«, in order to recycle plastic-rich waste streams completely and to a high standard. With the CreaSolv® process of the IVV, plastic recycling from highly complex and contaminated waste is achieved. UMSICHT's iCycle® technology enables the efficient thermo-chemical conversion of plastic-metal composites into energy sources and metal concentrates. By combining the two technologies, a holistic and economical recycling process for complex material composites is now being offered for the first time. Both processes have reached industrial maturity in recent years and are now being jointly introduced to the German and European markets.

Focus on packaging, waste electrical and electronic equipment and end-of-life vehicles

In the recycler, the plastic-plastic or plastic-metal composites usually end up in the fraction that is later incinerated. In this way, however, only part of the energy content is recovered. Metals, especially those with small grain sizes, are lost unused in the slag. So it is hardly surprising that of the almost 5 million tonnes of post-consumer plastic waste in Germany, only about 38% or 1.9 million tonnes are recycled. On the other hand, the demand for plastic recyclates will rise to a good 5.3 million tonnes in the medium term. IVV technology permits the selective and economical recovery of plastics such as PE from packaging, PP, PS and ABS from old electrical appliances or ABS from components of end-of-life vehicles or shredder light fractions. The residual fractions of the Creasolv® process contain valuable and rare metals as well as small amounts of other plastics. This fraction forms the starting material for the iCycle® process. By heating the material to 500 °C with simultaneous exclusion of air, high calorific value oils and gases are formed from the plastic component, while the metals are exposed. The resulting metal concentrate can then be marketed. »The outstanding product quality of CreaSolv® Recyclate allows it to be used for virgin material with almost no loss of quality,« explains Dr. Andreas Mäurer of the Fraunhofer IVV, explaining the process approach. »By coupling it with the iCycle® process, we will now make our process even more economical and at the same time make it possible to recycle many coveted metals.«

Critical metals from waste electrical and electronic equipment

Once the plastics have been recovered, the metal-containing material is fed into the iCycle® process. »With the help of the iCycle® process, it is possible to obtain a metal concentrate that can be marketed with revenues of over 2,500 € per ton depending on the input material. From the residual plastics, we simultaneously extract high-energy gases and oils that can be used to generate energy and supply both processes with energy,« explains Dr. Peter Hense of Fraunhofer UMSICHT. The combination of the processes offers recyclers several advantages: they receive plastic recyclates, valuable metal concentrates and at the same time generate energy sources that can be converted into electricity and thermal energy, for example with a combined heat and power plant. By expanding and adapting both processes, a process is also being developed for the first time that recovers the metals antimony and indium from old products. The European Union classifies these metals as critical for the supply of energy. Both are found primarily in old electrical appliances and are currently virtually not recovered.

Marketing

In the »kunstwerk« project, the strategic alliance between the two Fraunhofer Institutes will be further expanded within two years in order to jointly market the innovative technology package. This will enable future users to exploit the untapped potential of the recycling industry. In addition to the interconnection of existing pilot plants and the optimization of existing interfaces, a demonstration campaign will also be carried out using packaging plastics and light shredder fractions from end-of-life vehicles and old electrical appliances. Interested industrial partners have the opportunity to participate in the implementation of this test campaign.

Last modified: