Project: Phy2Climate

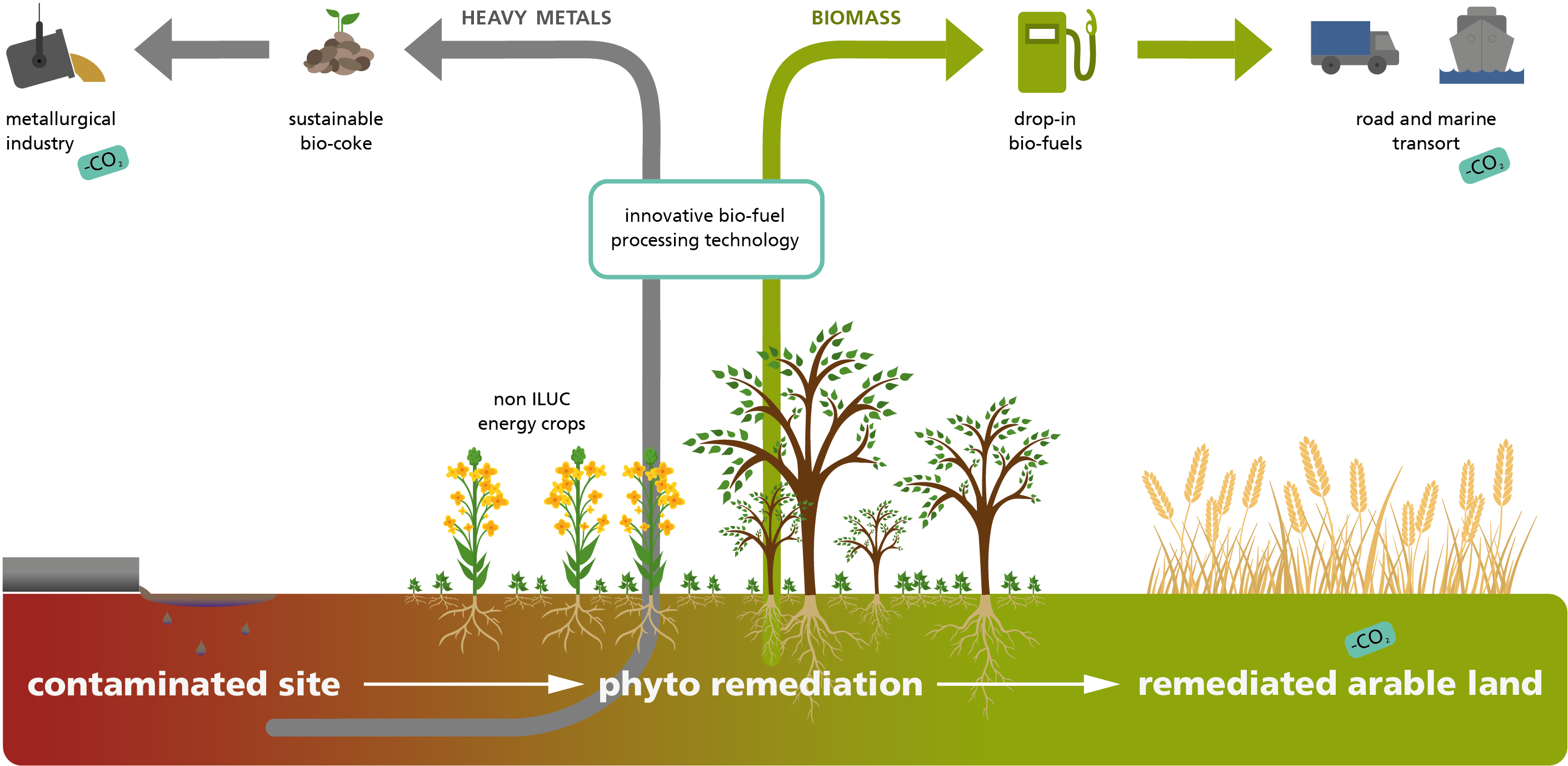

Phy2Climate - A global approach to reclaiming agricultural land through a combination of phytoremediation, biofuel production and climate-friendly copper smelting.

Contaminated industrial wastelands or former mining areas are areas that usually cannot be used for further agriculture without extensive remediation. The contamination by organic pollutants and heavy metals is so high that the cultivation of food is impossible.

Phytoremediation

A cost-effective approach to making these areas usable again is phytoremediation. This process uses plants that selectively absorb certain pollutants from the soil during the vegetation period. So-called hyperaccumulators can be particularly effective. However, such remediation requires several vegetation periods - years in which the land cannot be used.

In the Phy2Climate project, the plants are already used during the period of remediation: with the help of thermochemical conversion processes, they are converted into fuels and reducing agents (coke) for copper smelters after harvesting. On the one hand, the remediation areas are thus used productively; on the other hand, the biomass provision corresponds to a None-iLUC (indirect Land Use Change) approach, i.e. no forests or other food production areas have to be converted for energy crop cultivation.

EU project with 17 partners from 10 countries

As part of the project, five experimental plots will be set up in Serbia, Spain, Lithuania, Argentina and India for phytoremediation. The harvested biomass is brought to Sulzbach-Rosenberg for thermochemical conversion. The oil obtained from thermochemical conversion is further processed into diesel and petrol as well as marine diesel. The reducing agents produced are examined together with the company Aurubis for their suitability as a substitute for fossil reducing agents in the copper smelting process. By substituting fossil coke in the smelting process, the biofuel produced in the project will be CO2-negative in balance. According to the EU calculation basis, the savings in greenhouse gas emissions thus amount to 149%.

Phy2Climate also contributes to 16 of the 17 Sustainable Development Goals of the United Nations.

The project is funded by the European Commission with about €4 million. It involves 17 partners from ten different countries, spanning the continents of Europe, Asia and South America. The project started on 1 January 2021. Due to the COVID-19 pandemic, the kick-off meeting was held as an online event in early February.

Phytoremediation produces biochar and fuel

Project updates

Phy2Climate – Fraunhofer UMSICHT received project consortium

Update 07/2023

The project consortium of the Phy2Climate project met at Fraunhofer UMSICHT in Sulzbach-Rosenberg.

Start of conversion of biomasses to fuels

The project participants presented the progress made so far in the first half of the project and gave an outlook on upcoming tasks. In Phy2Climate, energy crops obtained from phytoremediation are used during soil remediation and converted into carbonisate, syngas and bio-crude oil.

The next project phase is dedicated to the conversion of biomass into fuels using the TCR process (Thermo-Catalytic Reforming) from Fraunhofer UMSICHT. During the tour through the pilot plants, the participants got an insight into the conversion process and inspected the plants on a laboratory scale.

Finally, a visit to the Hohenburg research site took place. Here, a large-scale demonstration plant is located, with which 50,000 liters of biogenic crude oil have been obtained so far.

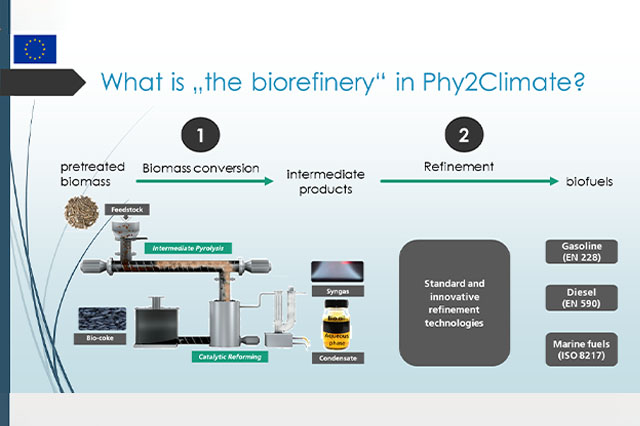

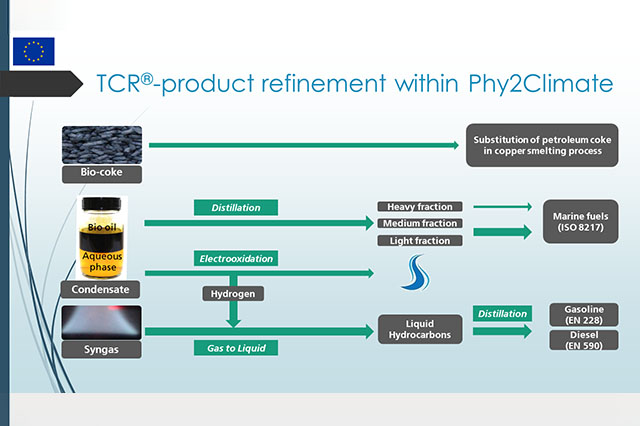

Construction of the pilot biorefinery completed

Update 10/2022

With the commissioning of a pilot-scale biorefinery, Fraunhofer UMSICHT successfully completed the first of three phases in the Phy2Climate project. The biorefinery will convert the energy crops obtained from phytoremediation into carbonisate, synthesis gas, and bio-crude oil. The latter are feedstocks for synthetic biogenic fuels that do not compete with food production. The carbonisate serves as a substitute for the use of fossil coke in copper smelting. The core process of the biorefinery is the »thermo-catalytic reforming« (TCR®) process developed by Fraunhofer UMSICHT, which converts the biomass from the phytoremediation into solid, liquid and gaseous raw products. The processing of the resulting raw products is then carried out using various technologies as part of the biorefinery. The bio-crude oil is distilled, the resulting synthesis gas is purified, compressed and then converted into liquid hydrocarbons using the FischerTropsch process. The hydrogen required for this is produced by an innovative electrochemical treatment process of the aqueous phase. At the meeting of the entire project consortium in Spain, sub-project manager Christopher Kick from Fraunhofer UMSICHT presented the current project status.

Components of the biorefinery and explanation of the product refinement process

more information

Video on the background and objectives of the project

Energy crop conversion to drop-in biofuel and bio-coke

Dr. Ing. Christopher Kick

Last modified: