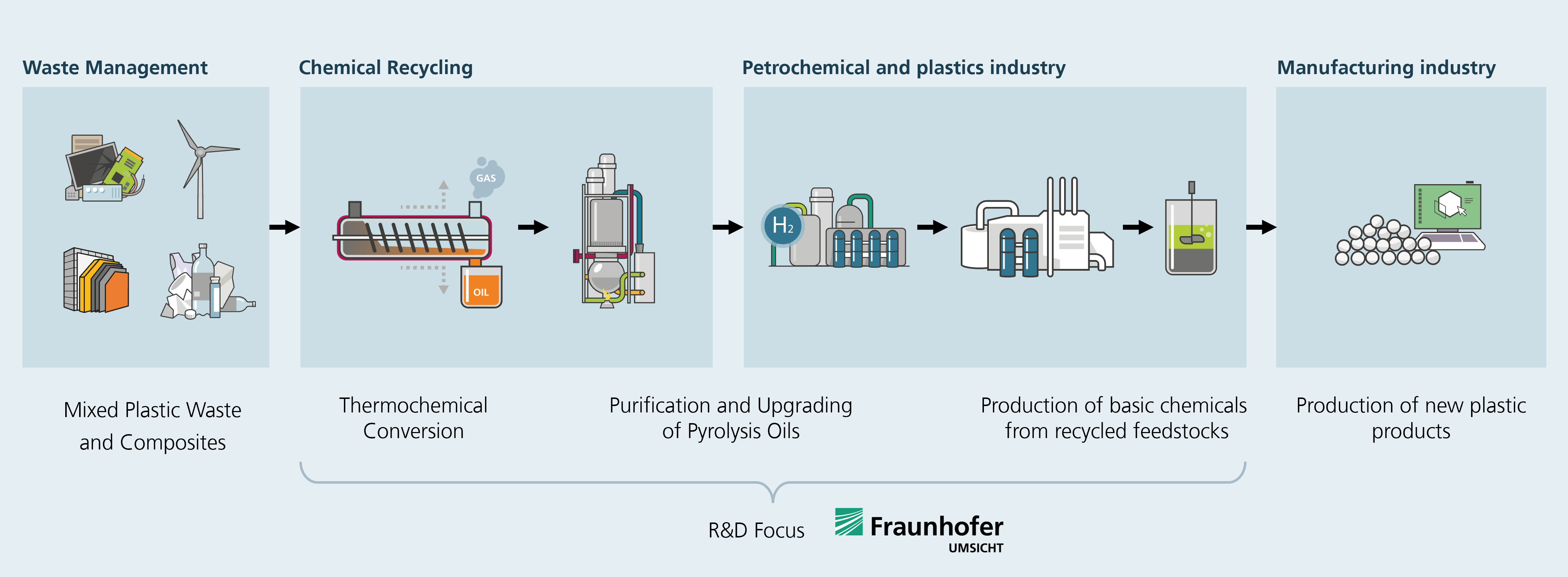

From waste to new product: Chemical recycling (also known as raw material recycling or feedstock recycling) has the potential - as a supplement to mechanical recycling - to achieve a more efficient use of plastic waste as raw material. Plastics that are currently not recycled can thus be reused as an alternative to incineration.

The aim is to close the value chain from plastic waste to recycled virgin material, especially for sensitive product areas such as food packaging, toys or medicinal products.

Of the 6.1 million tonnes of plastic waste generated alone in Germany in 2017, 2.8 million tonnes were materially recycled. 3.2 million tonnes were energetically recycled, i.e. most of it was incinerated. These were mainly mixed plastic waste and sorting residues from mechanical recycling.

Plastic impurities prevent recycling

Contamination of plastics by glass, metals, fibres, wood, paper, pigments, additives or flame retardants also makes recycling more difficult, because the range of application of the recyclates produced is severely restricted. Especially in these material flows, chemical recycling should be considered, because it offers the chance to obtain basic chemical compounds for plastics production from these fractions. If the raw materials can be provided in virgin quality, free of any impurities and pollutants, plastic products can be reused in the future without cycle limits.

Technology overview chemical recycling

Possible technological processes for chemical recycling include solvent-based processes such as solvolysis, but also hydrothermal microwaves and thermochemical processes (pyrolysis, gasification). The choice of the respective process depends strongly on the composition and contamination of the feed material.

Pyrolysis facilitates decentralized plant operation

Thermochemical processes are particularly suitable for highly mixed and contaminated material flows. One advantage of pyrolysis in particular over gasification is the possibility of decentralised operation.

Fraunhofer UMSICHT in Sulzbach-Rosenberg looks back on many years of experience in the field of thermochemical processes. With the iCycle® technology, it has already been possible to convert complex waste materials such as electronic scrap and composite materials on a demonstration scale (70 kg/h) and recover fibres, minerals and metals in the process.

In the field of biomass conversion, the TCR technology provides a platform for the synthesis of green crude oil for power or hydrogen production.

Advanced Recycling

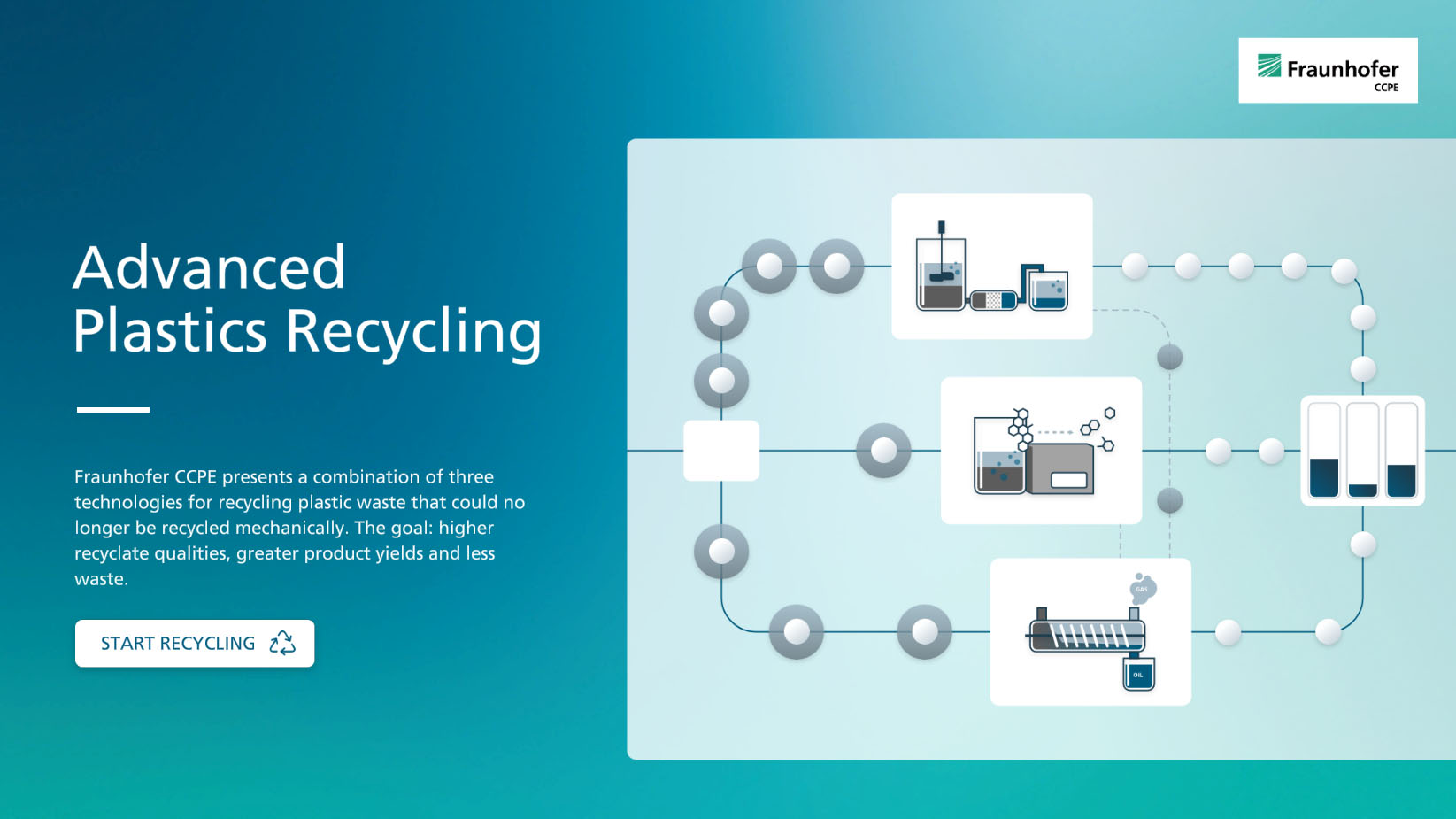

On behalf of the Fraunhofer-Gesellschaft, Fraunhofer UMSICHT, together with five other Fraunhofer institutes in the Fraunhofer CCPE cluster, is using plastics as an example to research how the sustainable transformation of an entire value chain can take place under principles of the circular economy.

We use advanced recycling technologies such as physical recycling technology, solvolysis and pyrolysis to recover polymers and monomers from the industry-specific life cycles of the plastic, which can be immediately further processed and used for various applications. Using feedstocks, additives and catalysts, we provide the appropriate test environment.