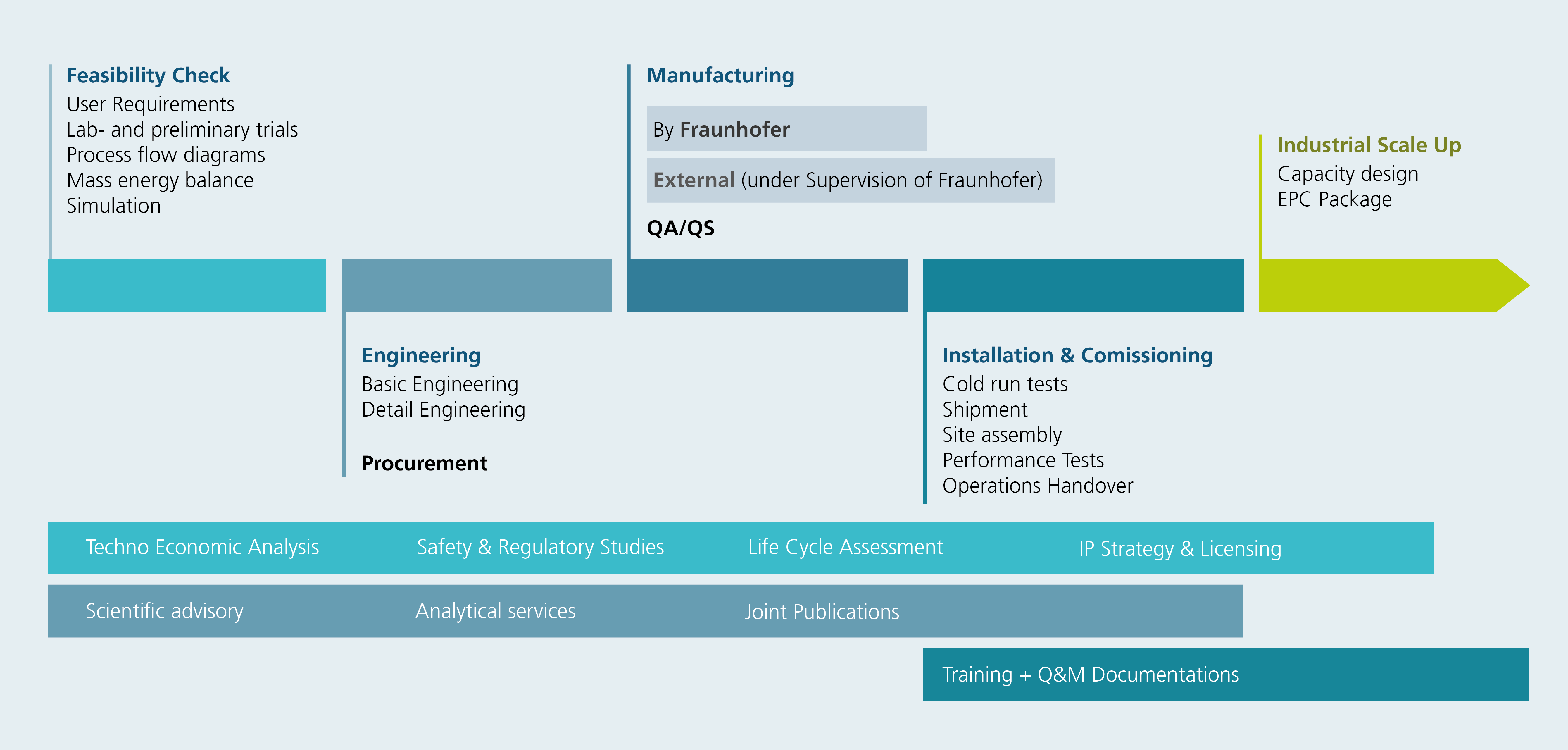

We develop, engineer and manufacture customized pyrolysis plants

At Fraunhofer UMSICHT, we develop, design, and construct pyrolysis research plants for universities, research institutions, and corporate clients.

We combine our scientific work in thermochemical carbon conversion technologies and clean combusiton technologies with specialized engineering and manufacturing of process equipment.

Whether you require a prototype unit, a pilot plant, or a demonstration-scale installation, our specialties lie in thermochemical and thermal process engineering, focusing on pyrolysis reactors.

To deliver cost efficiency, we combine tailored manufacturing of specialized components in our own workshop with seamless integration of pre-fabricated modules.

Assembly, test runs, and commissioning are handled by our experienced team of technicians and engineers.